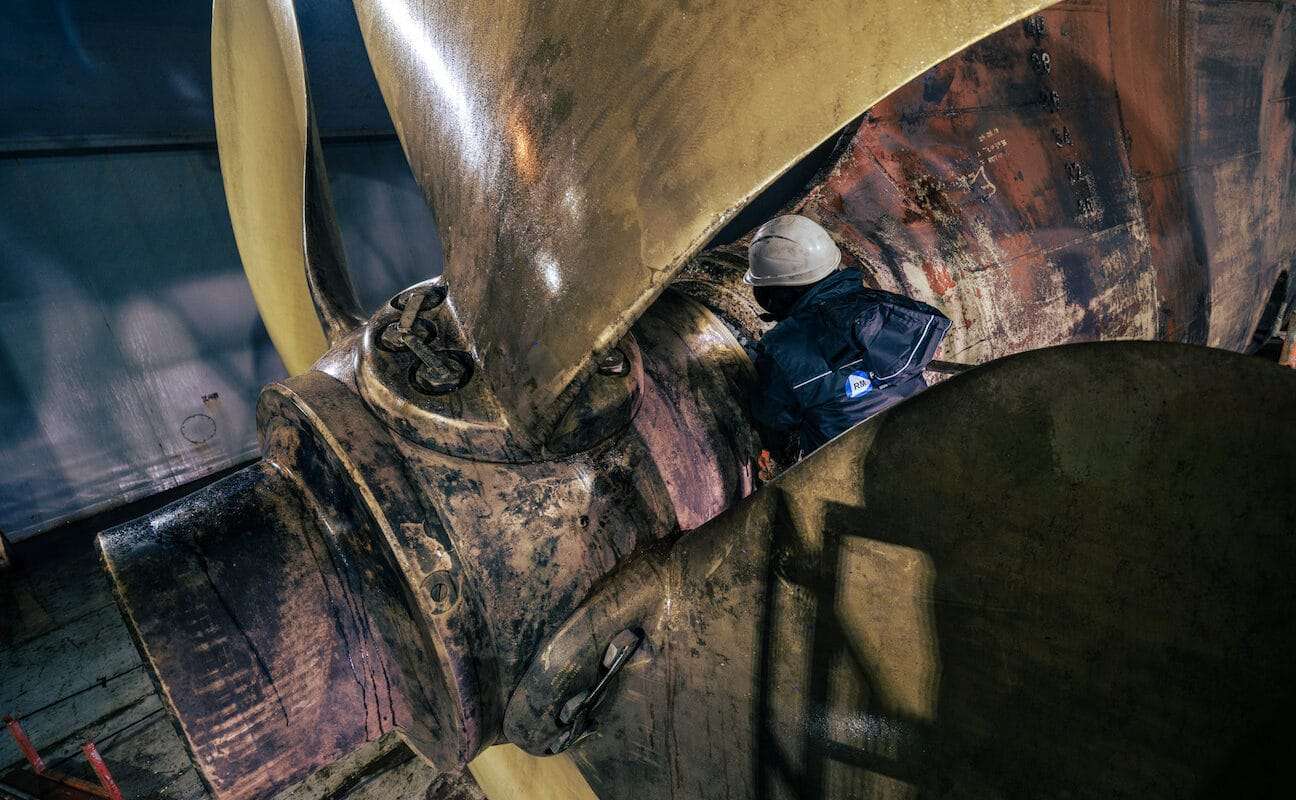

Stern tube seal replacement

Stern Tube Seal Replacement Services

RM Propulsion specializes in stern tube seal replacement and offers a comprehensive range of services, including overhaul, repair, and troubleshooting for your vessel’s stern tube system. Stern tube seal maintenance is essential and should be carried out at least every five years to maintain the efficiency and safety of your propulsion system. Above all, we are ready to assist with emergency repairs whenever necessary to minimize downtime.

Our service technicians can service all common brands including:

Global Availability

Our engineers are stationed in Turkey, Estonia, China, and the Netherlands, ensuring that we can provide stern tube seal replacement services worldwide. If your vessel isn’t near one of these countries, we can still dispatch our engineers directly to your location. Whether you need stern tube seal bonding or repairs afloat, we’re equipped to handle it efficiently.

One-Year Warranty on Stern Tube Seal Bonding

For peace of mind, all stern tube seal bonding services come with a one-year warranty, ensuring the quality of our work and the continued reliability of your vessel’s stern tube system.

Planning Your Stern Tube Seal Service

At RM Propulsion, we work with you to plan the full scope of the stern tube seal service. We coordinate with your superintendent, crew, and shipyard to ensure everything is in place for a smooth operation.

High-Quality Seals for Stern Tube Seal Maintenance

We offer stern tube seal service using either our own Ocean Seal® type-approved seals or spares from your selected brand. Not only do we guarantee high-quality seals, but we also ensure compatibility with your specific stern tube system.

Efficient Overhaul, Bonding, and Repairs

Our engineers provide comprehensive service for stern tube seal replacement, including overhauls, bonding, and repairs. We ensure that your stern tube system is fully functional and protected. Typically, a normal overhaul for the AFT and FWS seals takes 3 to 4 working days under perfect circumstances, assuming no uninspected details arise during the process.

Dry Dock or Afloat Stern Tube Seal Service

We offer flexibility in performing stern tube seal replacement either in dry dock or afloat, depending on your vessel’s needs. A stern tube overhaul is typically done in dry dock, where full access allows for thorough inspections and repairs. However, in some cases, if there is a leakage or other issues requiring immediate attention, the work may need to be done afloat. This flexibility ensures we can meet your requirements, whether your vessel is in port or operating at sea.

Emergency stern tube seal replacement

Looking for an expert opinion on your vessel’s stern tube seal? Need advice on stern tube seal bonding? Our expert engineers can provide in-depth inspection and troubleshooting services to help keep your vessel running safely and smoothly and minimise downtime.

For urgent matters & troubleshooting please contact us now. We will contact you soonest by email or phone.

Water ingress or Oil leakage

Depending on your situation, we can carry out a service job either in the shipyard or afloat. If you’re concerned about:

- Stern tube seal leakage;

- Oil leakage;

- Water ingress;

- General troubleshooting;