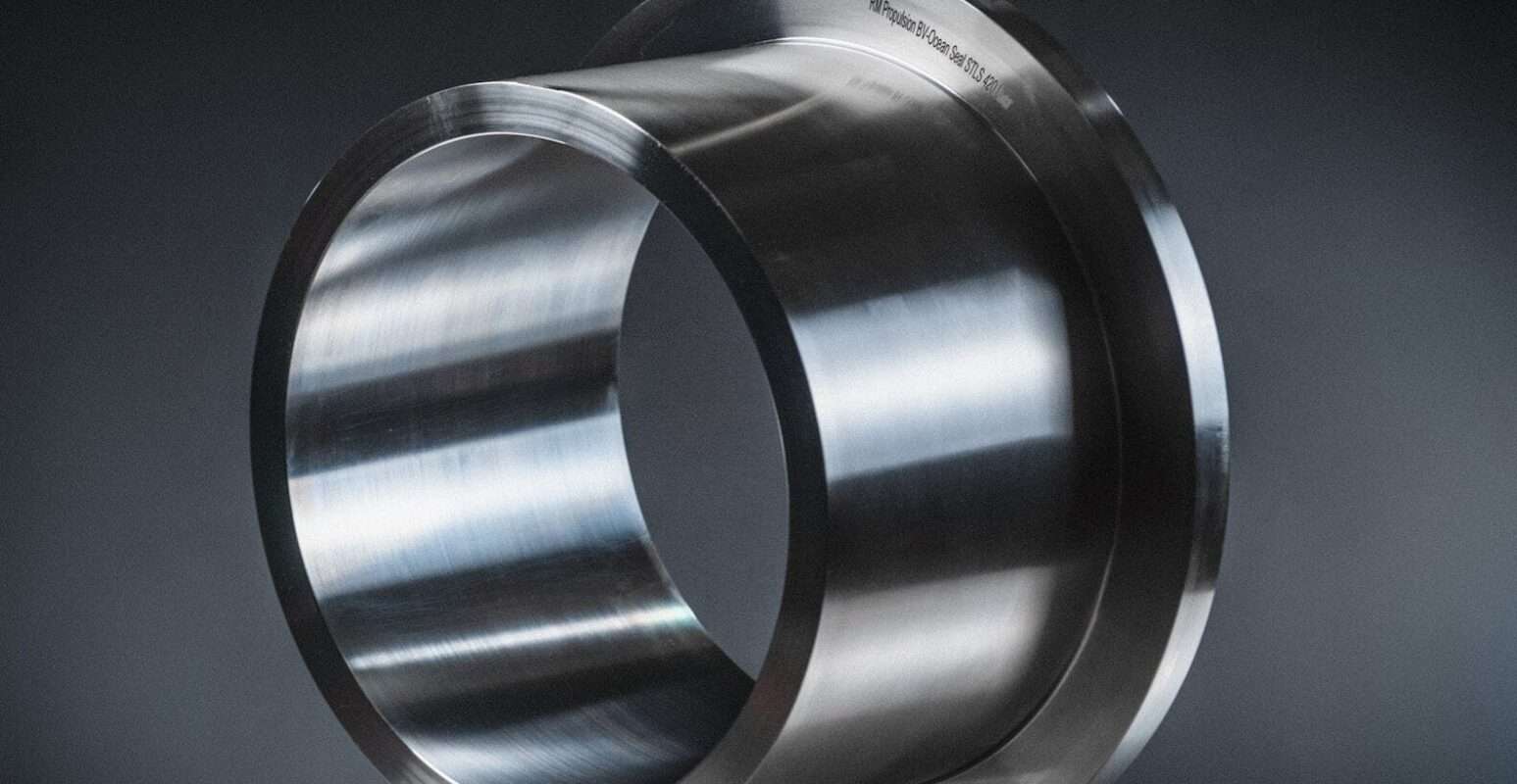

Stern tube seal chrome steel liners

As part of our overall stern tube seal offering, we provide chrome steel liners suitable for all standard systems.

Our aft and forward chrome steel liners are OD-finished, because every liner needs to fit perfectly, other machining can be carried out by the customer.

What do chrome steel liners do?

The stern tube seals in oil-lubricated lip-type systems run on a bush or liner. Over time, the seals create grooves in the liners, which shows that the liner is doing its job of protecting the propeller shaft.

When we replace the seals. We always check the liner surface, because new seals should run on a fresh liner surface. If the grooves are getting to deep, we need to skimm the liner, this all depends on the liner tolerance if this is still a possibility.

Or we can add or remove a distance ring on the AFT side, between the seal housing and the stern tube. We will move the entire seal box to a different position on the liner. So we can add or remove the ring.

Thus, for the AFT side we have two options before you have to purchase a new liner, however for the FWD side we can only machine or renew the liner.

We are always looking for the most cost efficient way for our customers.

Compatibility Chrome steel liners & Stern tube seal systems

Our AFT and FWD chrome steel liners follow the industry standard design and are compatible with the following stern tube systems:

- SKF Simplex® AirSpace, Compact SC-1, Compact SC-2

- Kobelco® C, CX, DX, AX

- Kemel® C, CX, DX

- Wärtsilä® Airguard, MK-2, OLS2, OLS3, OLS4

- Lagersmit® Supreme Seaguard Ventus

- IHC Lagersmit® Supreme

- Lips® MK-2

- John Crane® MK-2

- Waukesha® MK-2

- Chuetsu® MK-2

- Dover Japan® MK-2

- JMT (Japan Marine Technology®) MK-2

- Deep-Sea Seals® MK-2

*RM Propulsion has no commercial relationship with any of the mentioned companies or one of the brands within their groups. We are an independent company in the marine industry.

Chrome steel liners lifespan

Once you have two sets of grooves on the liner, it can be removed and machined to produce a fresh surface. This leaves it ready for another two seal overhaul periods. So skimming the liner is a good option, for the FWD and the AFT side.

Usually, a distance ring will have been installed during the initial build process. At the five-year dry-dock, this distance ring will be removed, allowing the seal to run on a fresh surface.

At the ten-year dry-dock overhaul, the liner will be removed from the shaft and machined in the workshop. The distance ring can then be reinstalled, and the liner may be used for another ten years.

“A note on ceramic-coated liners”

Issues ceramic coated liners

These issues include coatings chipping off and damaging the seals, as well as severe wear and signs of overheating on the stern tube seals.

We concluded, in consultation with our supplier, that the stern tube liner needs a certain amount of surface roughness to distribute oil correctly and provide proper lubrication. We have established a guideline safe range for the surface roughness between 0.4 and 0.8 Ra.

A brand-new ceramic-coated liner is likely to meet this roughness standard, but after five or ten years of operation, the polished track on the liner will likely no longer be within this range. In these cases, we recommend installing a distance ring if possible. If this is impossible, we recommend replacing the liner with a new chrome steel liner.

Effect on warranty

If a ceramic coated liner has already been in operation and a distance ring cannot be installed, and if the customer does not wish to replace the liner, the surface roughness must be measured. Although the roughness is within the safety range, we cannot grant a warranty.

RM Propulsion will not grant any warranty on the stern tube seals & overhaul service with a ceramic coated liner.